CONSTANT VELOCITY JOINTS

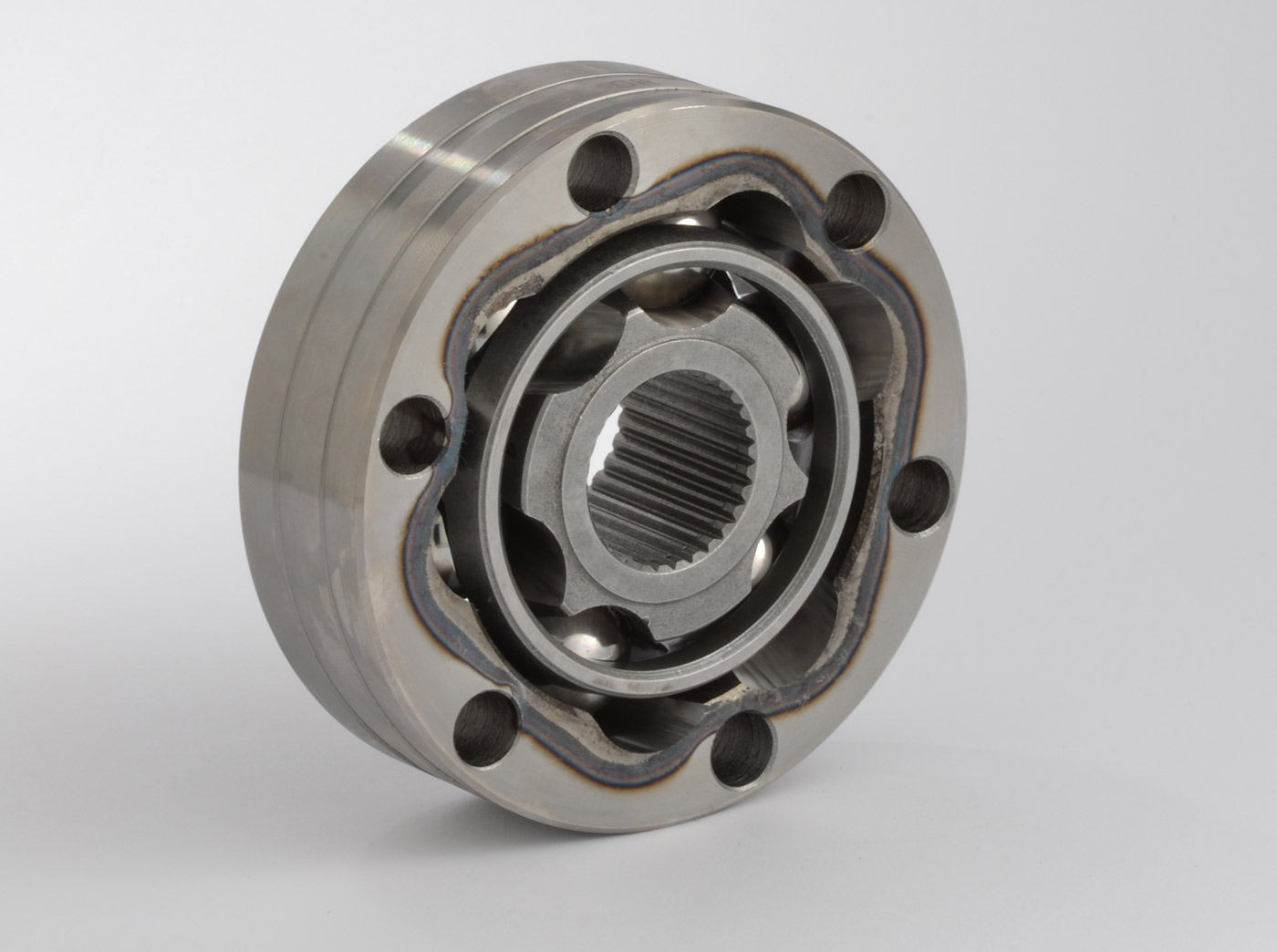

Constant velocity joints allows maintaining the same shafts rotation speed (kinematic mechanism).

Constant velocity joints facilitate the steering of the vehicle by minimizing the stresses, which would compromise the transmission time.

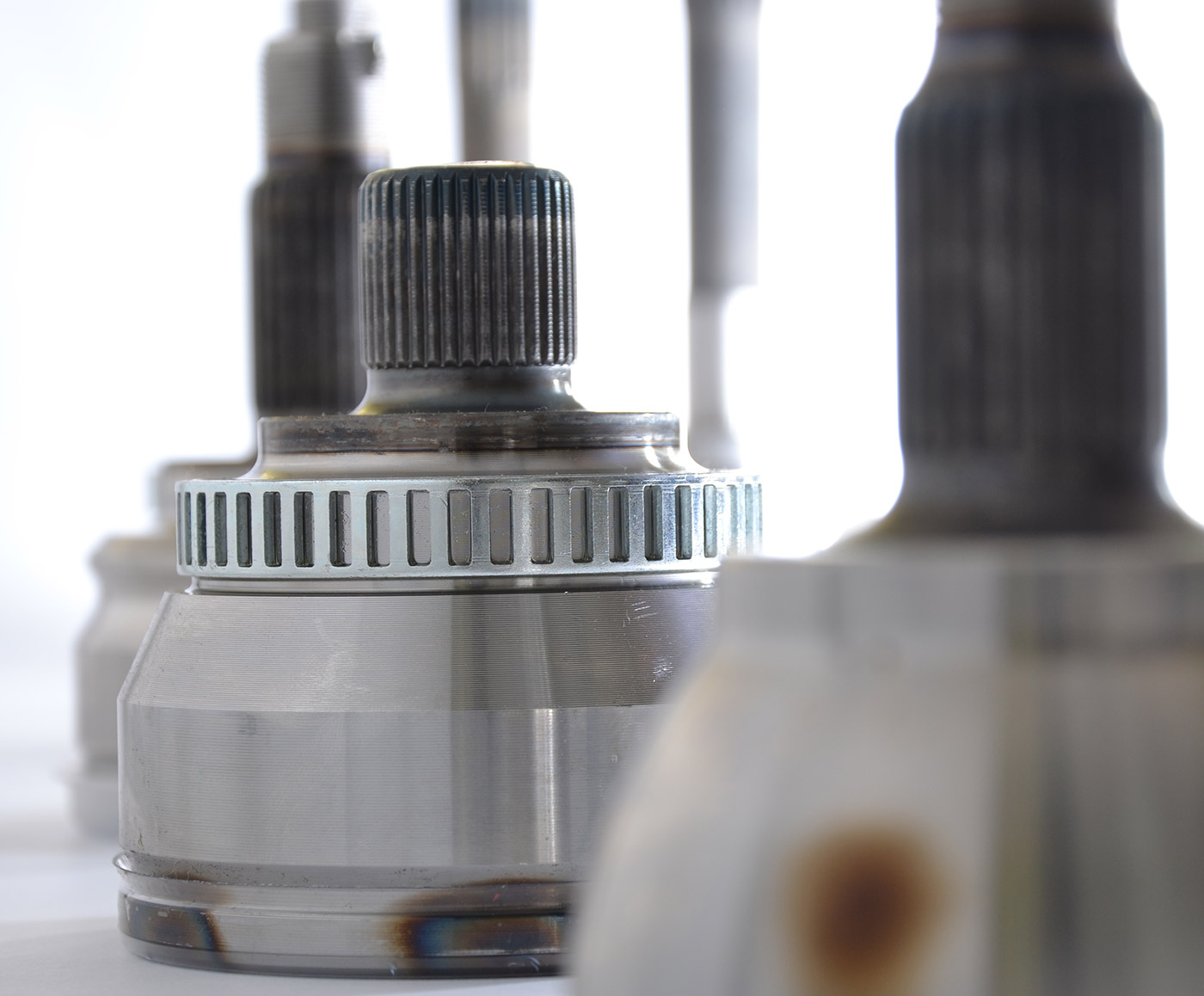

In terms of definition, constant velocity joints are also known with name of homokinetic or CV joints and allow a drive shaft to transmit power through a variable angle. The transmission also happens at constant rotational speed and without any appreciable decrease in play of friction.

Constant velocity joints are mainly used in vehicles with front wheel drive, but also in several modern rear wheel drive cars with independent rear suspension. In this last case, constant velocity joints are used at the ends of the rear axle halfshafts or on the drive shafts.

Usually, constant velocity joints are protected with the aid of a gaiter filled with molybdenum disulfide grease and a rubber boot. Usually, constant velocity joints can wear quickly if cracks and split allow the entering of contaminant and the leaking of grease. This way, the friction parts cannot get a proper lubrication and end up being damaged by minor particles penetrating the part. At the same time, water can also cause metal components to rust and corrode.

That’s why a normal usage of constant velocity joints must take into consideration the regular wear of the boots, normally appearing as small cracks close to the wheel, the vibrations and up and down motions are more redundant. Finally, external factors such as packed snow, stones or uneven and rocky paths can also cause cracks and tear in the areas that are located close to the axle.

In conclusion, constant velocity joints can be described as universal joints that are used in the drive train of front-wheel-drive cars. Their main quality is to operate effectively even when the shafts being connected meet at a sharp angle.

Another interesting feature connected to these spare parts is that, whatever the operating angle of the constant velocity joint, the rotational speed of the output shaft always remains the same as that of the input shaft. Constant velocity joints are purposefully designed to be able to bend in any direction while continuing to turn the drive wheels at a constant speed, and to create a smooth transfer of torque from the driven shaft to the driving shaft without any fluctuations in the speed of the driven shaft.

PRODUCTS